Project Management

We have six (8) professional English-speaking project management engineers to follow tooling design, tooling making and testing to provide services as below for you:

- Early Stage Engineering Support

- Quality Requirement Planning

- Material Selection Consultation

- Mold Concept Planning

- Design for manufacturability Services

- Mold flow analysis Services

- Product Testing Services

- Material Testing and Validation Services

- Product Development Services

- Product Design Assistance

- Professional Engineering Services

- Projects Schedule Planning

- Tooling Weekly Process Report

- Mold Trailing

- Mold & molding validation report

- Exception handing in logistics

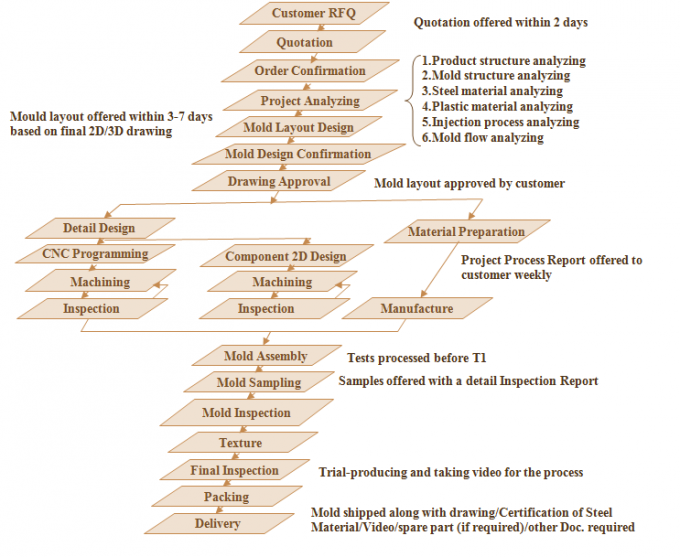

DFM & Mold Design

We provide engineering guidance to help you design moldable parts that are optimized for manufacture. From tool design concepts to process development and validation, we ensure that all aspects of production meet the ultimate goal of producing high-quality injection molded parts.

Product Design Assistance

Support in the design of product features, specs and industrial design follow. We can support you in development of your new projects or re-design current products and implement these steps on behalf of clients by meeting in person and teleconferencing with you and your sales & marketing and technical people each step of the way.

Product Development

- Early Stage Engineering Support

- Quality Requirement Planning

- Material Selection Consultation

- Mold Concept Planning

- Part Optimizing

- Design For Manufacturing

- Cycle Time Optimization

Mold Design Support

- Mold drawing 2D

- Mold drawing 3D

- Design for Manufacturable

- Mold Design Checked

- Mold Design Specification

- Mold Design Optimized

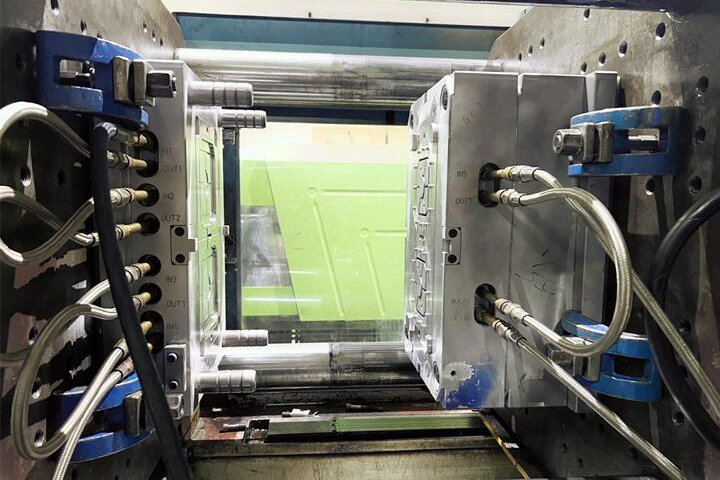

- Cooling Design Optimization

Engineering Software

- Auto CAD

- Unigraphics NX

- Autodesk Moldflow

Mold Manufacturing

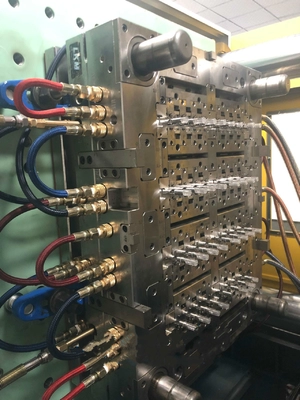

Our mold making department is capable of constructing numerous types of injection molds with significant experience in most modern mold construction systems.

- High cavitation molds

- Appropriate hot runner design and selection.

- Low cycle molds (5000 shots)

- High cycle molds (over 10 million)

- Multi-Material molding (2k) and insert molding

- Gas Assist molding

- Foam Injection techniques

- Close tolerance Molding

- ElastERBIWAric molding

- Compression molding

- In-Mold Labeling

- Thin wall molding

- High Heat molding

- Precise part moldings

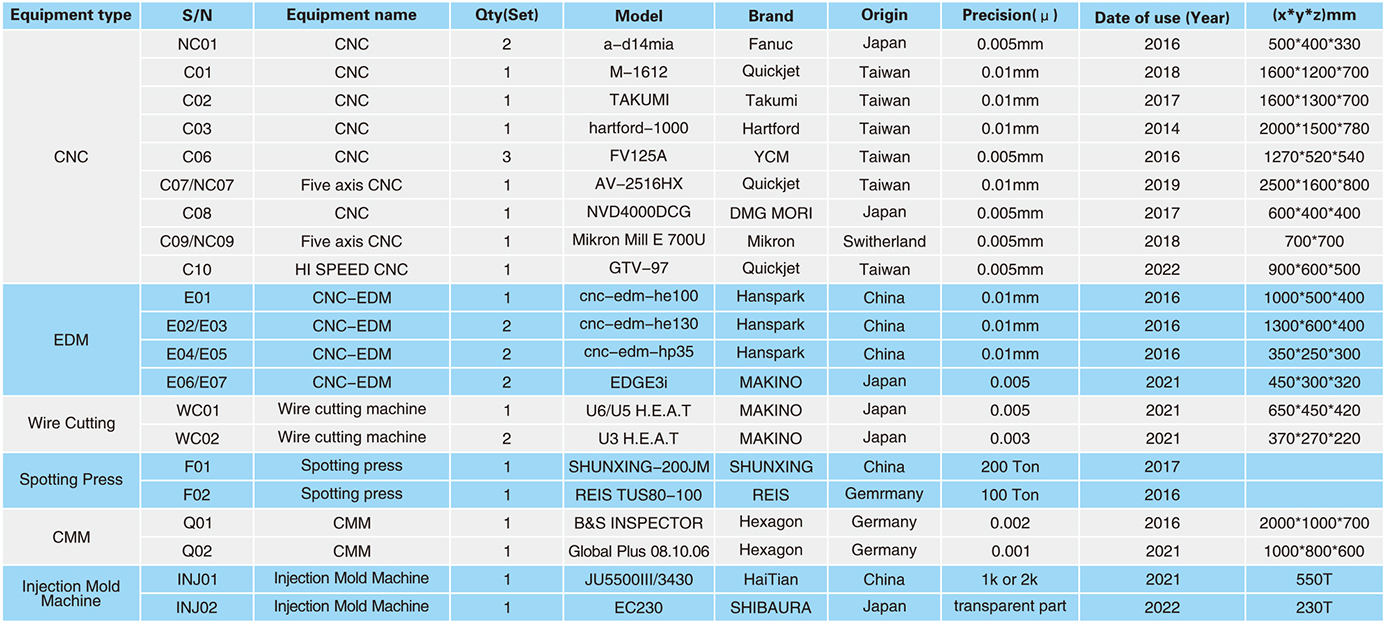

Main Equipment List

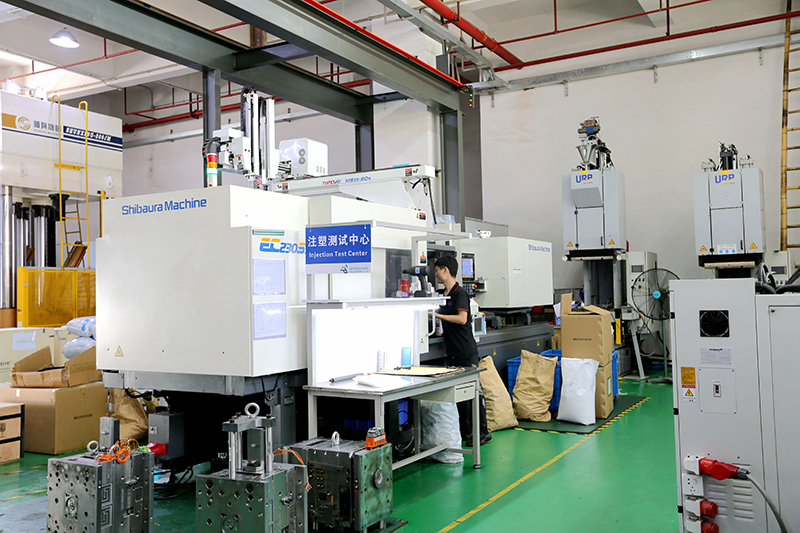

Mould Trial

Once the molds are completed, we will set it up for mold trial to verify the injection mold mechanism functionality and product completeness/accuracy, 5-10 shots free samples will be sent to customers for evaluation.

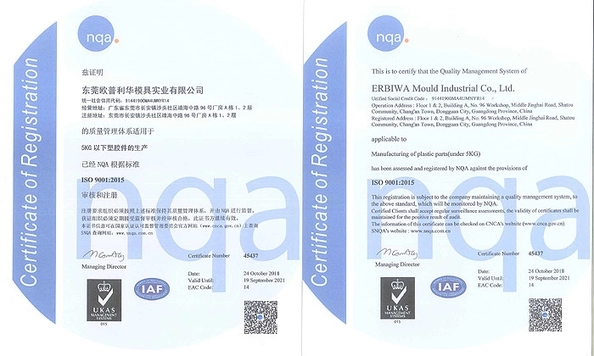

Quality Control

We are confident that our QA team will ensure the quality of your project along with the newest equipment, which we are always updating, to cater to the demand of custERBIWArs.

- Mold Design Control

- Mold Steel Hardness Inspection

- Mold Electrodes Inspection

- Mold Core and Cavity Steel Dimension Inspection

- Mold Pre-Assembly Inspection

- Mold Trial Report and Samples Inspection

- Pre-Shipment Final Inspection

- Export Product Package Inspection

Deliver,Shipping And Serving

Our QC will 100% inspect the mold and parts before shipping and provide detailed inspection report.

After pass inspection, we will carefully clearn the mold and parts.

1) .For moulds, they will be coated one-layer anti-rust oil firstly,and then covered thin films overall the mould, finally pack into non-solid wooden case.

2) .As for plastic products, we will pack into standard export cartons or as per customer’s requirements.

Injection Molding production

ERBIWA is a full service plastic injection molding manufacturer in custom manufacturing. With our experienced tool makers and setters, we can achieve optimal product output in a minimal amount of time. We mold your products to meet your specifications and put them trough our quality inspection department to guarantee accuracy and quality at all times.

- On-site injection plastic mold repair & maintenance

- 24-hour plastic molding manufacturing shifts

- Long and short plastic injection molding production runs

- Insert molding, dual-color molding service

- Extensive capabilities to process engineered raw materials and complex filled-polymer compounds

- Large and small parts

- Low and high volume

- Tight Tolerance and Quality Controls

- 1 Clean Room Molding (100K class) with 20 electric molding machines

- 76 Injection Machines (Range from 50-1300T, electric x24, vertical 1x, two shot x3), we can achieve optimal product output in a minimal amount of time.

Auto Part Molding

Double Shot Injection Molding

Electronic Molding

Test

Insert Molding

Medical Injection Molding

Assembly and Secondary Operations

Our team is fully capable of managing secondary operations, assembly and final packaging ready for shipment to your warehouse.

Silkscreen

Paint

Assembly

Test

Kitting

Packaging

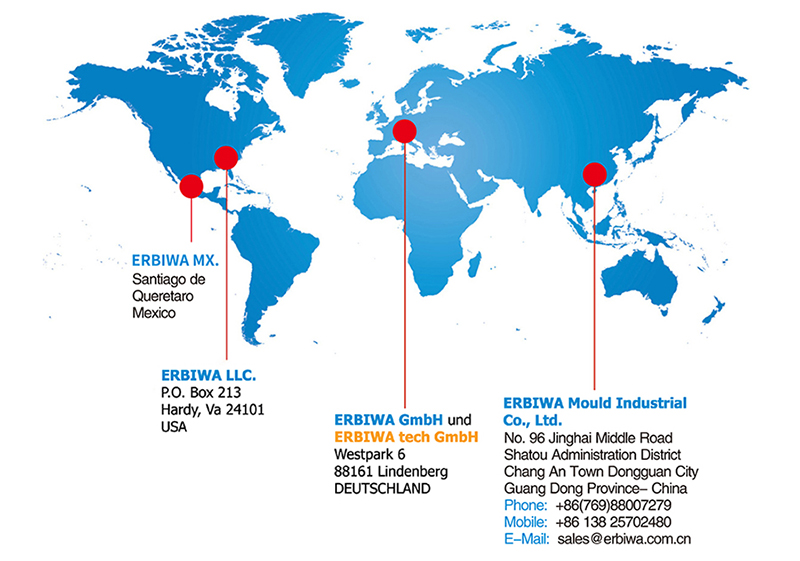

After Sales Service Network (ASSN)

Using our global network to service our customers around the world.

Loyalty to the customer

Purposeful and result-oriented implementation

Confidentiality of confidential data of business partners Establishment of long-term business relationships for the benefit of both partners